In recent years, gas explosion incidents in high-rise buildings and densely populated areas have occurred frequently both domestically and internationally, resulting in severe casualties and property damage. On December 11, 2024, an explosion occurred in a high-rise residential building in Shenzhen Bay, resulting in one fatality. These incidents are typically caused by gas leaks, and traditional gas leak detection methods have numerous shortcomings. Traditional methods rely on manual inspections and simple handheld gas detection devices, which are inefficient, unable to cover all potential risk points, and susceptible to environmental interference, leading to inaccurate and untimely monitoring results.

For densely populated high-rise buildings where gas leaks pose a significant risk, laser gas inspection is an innovative technology that can significantly improve detection efficiency and reduce costs. The laser solution employs advanced tunable diode laser absorption spectroscopy (TDLAS) and laser remote sensing technology to quickly detect even the smallest leaks of methane and ethane in gas and issue an alarm. Its detection accuracy spans from the ppm level (parts per million) to the ppb level (parts per billion), representing at least a 1,000-fold improvement over traditional electrochemical devices. In recent years, with the rapid development of drone applications and wireless signal transmission technology, the laser monitoring solution, which complements these advancements, has demonstrated significant advantages in indoor gas leak detection for buildings in numerous domestic and international cases, thanks to its high precision, sensitivity, and real-time capabilities.

01

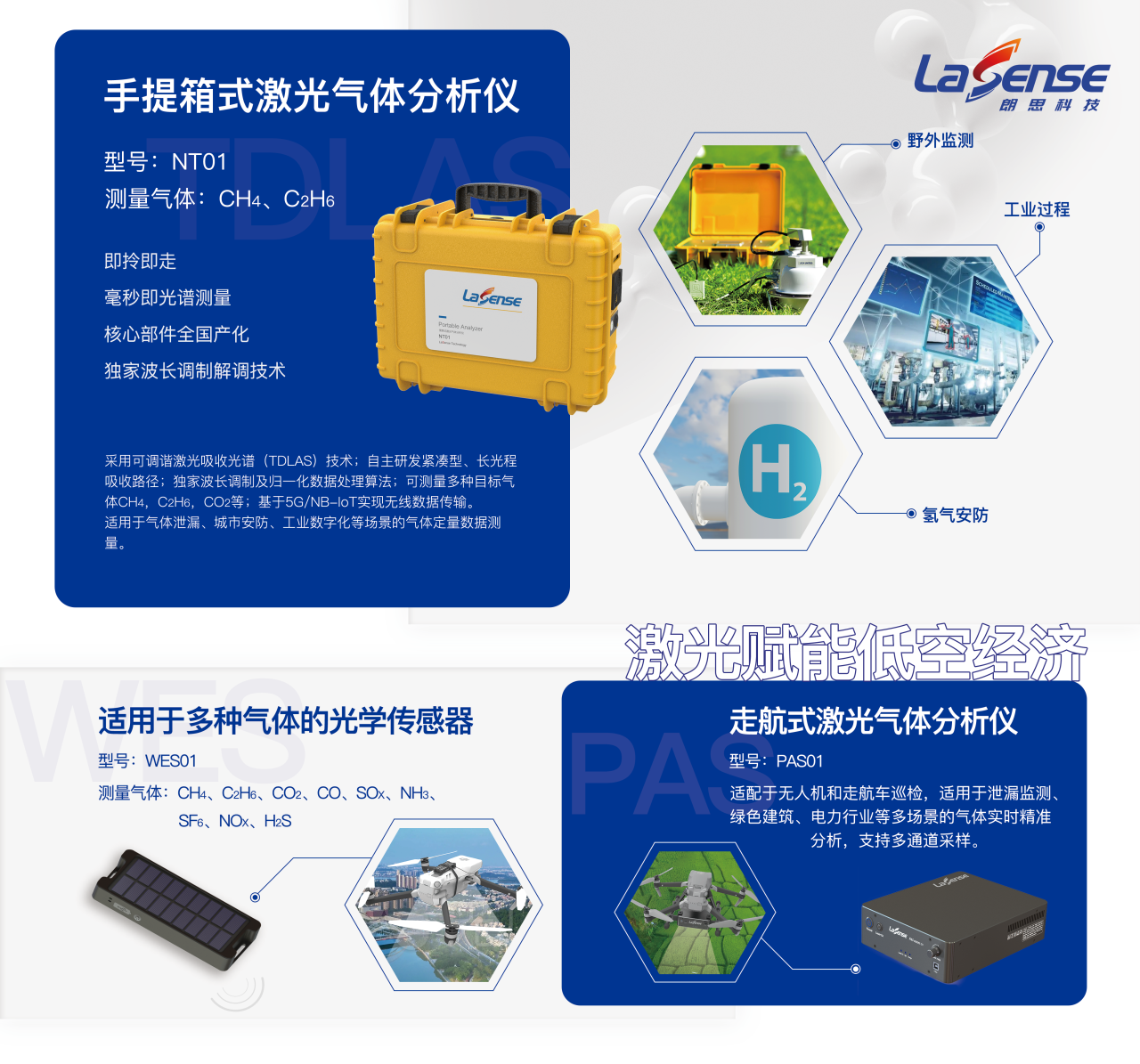

UAV-mounted laser inspection

Laser analyzers can achieve millisecond-level, high-accuracy gas monitoring, while UAVs can reach areas inaccessible to staff from the outside, enabling rapid and comprehensive inspections. By mounting ultra-high-precision laser methane remote sensing analyzers on UAV flight platforms, they have been widely used in gas leak inspections across various complex industrial scenarios over the past five years. For example, in the power sector, drone-mounted lasers can obtain three-dimensional point cloud model data of power transmission lines, achieving full coverage of target gas concentration data within the inspection path range. In gas monitoring, for high-rise buildings and older communities with significant safety hazards, drones can also cover large areas, particularly enabling timely detection of leakage points in enclosed building units that are inaccessible.

Currently, drone-mounted laser inspections can accurately detect low-concentration methane gas leaks indoors from a distance of 50 to 200 meters. While ensuring compliance with inspection regulations and protecting residents' privacy, the actual detection limit can reach 5 ppm at a distance of 20 meters through double-paned glass. In terms of detection efficiency, the combination of drones and lasers can inspect 1,000 households per day, which is more than 50 times faster than manual inspections. and eliminates the risk of personnel entering hazardous environments.

02

Portable Handheld Laser Analyzer

As shown in the figure, the portable laser analysis device is easy for staff to carry. For residential units where leaks have been reported by residents or are known to be potential leak sites, the device can be quickly deployed in the area requiring detection to perform rapid and precise sampling and gas component analysis. Compared to the sensitivity limitations of traditional handheld electrochemical and infrared devices, even trace-level gas leaks can be detected instantly upon occurrence, with the ability to identify gas type and specific concentration values, enabling timely determination of whether it is a gas leak and whether it has reached the risk threshold for combustion or explosion.

03

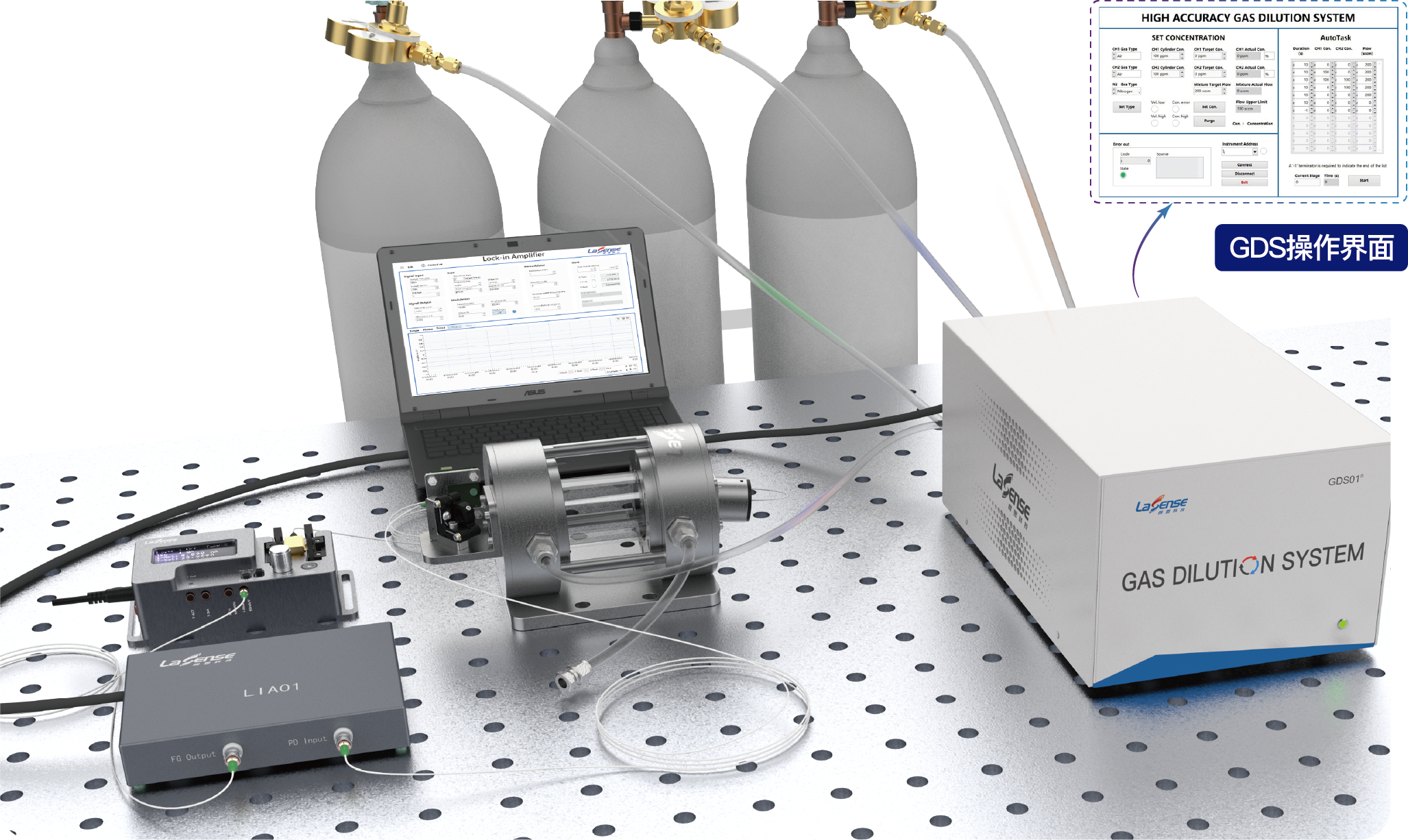

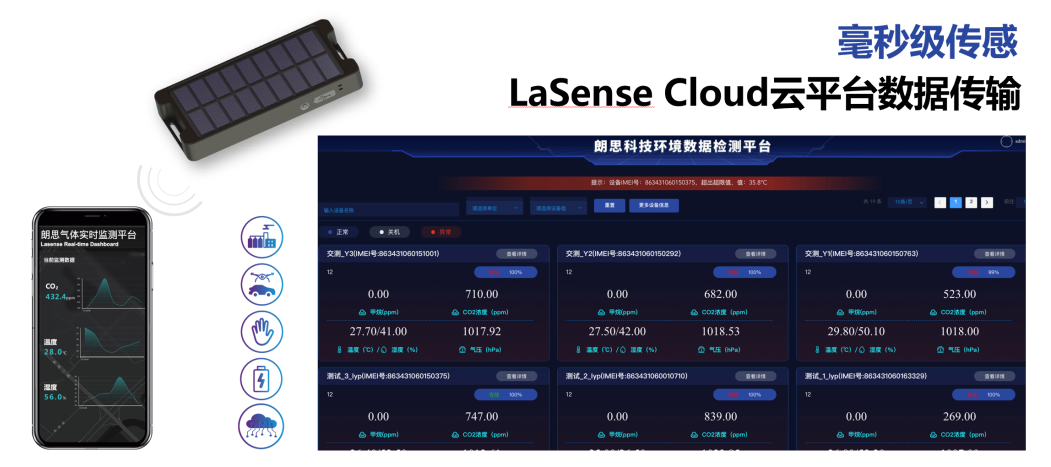

Millisecond-level sensing + wireless transmission of data to the cloud platform

Laser absorption spectroscopy technology has been applied to household gas monitoring sensors, and in recent years, manufacturing costs have been significantly reduced. This technology can provide real-time leakage safety data that is more accurate, reliable, and cost-effective than traditional gas sensors. Lasers, with their excellent selectivity, can quickly analyze the characteristics of the measured gas. Through intelligent algorithms, they can automatically exclude the influence of interference factors such as methane gas, accurately identify gas leakage information, and effectively avoid false alarms. In terms of timeliness, 5G and NB-IoT technologies can transmit data such as hazard warnings, gas leakage conditions, inspection times, and location information in real-time to the pipeline inspection platform, automatically generating inspection reports to achieve closed-loop centralized management of safety hazards. This establishes a digitalized and intelligent safety management system for graded control of gas safety conditions.

Addressing gas explosion hazards in unregulated buildings

In the field of industrial safety monitoring both domestically and internationally, including manholes, pipelines, above-ground gas stations, and petrochemical stations, there have been numerous successful cases of laser analysis equipment being used to monitor natural gas, hydrogen, and other gases. These cases include drone flight inspections, inspection vehicles, gas laser radars, handheld devices, and next-generation sensors. These products complement each other, enabling gas monitoring solutions to “reach both sky and ground,” preventing accidents before they occur and successfully avoiding safety incidents. These cases demonstrate that laser gas monitoring technology holds significant value and potential for improvement in enhancing the safety of daily operations and emergency management of gas pipeline networks in residential communities. The significant advantages of laser technology—fast measurement, high accuracy, and non-invasive operation—enable more efficient prevention and response to gas leaks, shifting from a “reactive” approach to an “active” regulatory model, and providing robust technical support for gas safety in high-rise buildings.