Natural gas pipelines, as a key infrastructure for energy delivery, methane (CH4) and ethane (C2H6) in municipal pipelines are the focus of monitoring. Laser gas sensing technology provides comprehensive support for safe pipeline operation and quality control by accurately detecting pipeline gas concentration and composition and distinguishing between methane and ethane leak sources and concentrations in real time. This technology provides an important guarantee for efficient natural gas transport and safe management of urban gas pipeline networks.

LaSense Technology's laser gas analyzer series (MT01 High-Precision Greenhouse Gas Laser Analyzer, NT01 Portable Laser Gas Analyzer, HT01 ICOS Laser Hydrogen Analyzer, etc.) adopt leading spectroscopic technology with high sensitivity and accuracy, and are widely used in the fields of ESG digital management, energy safety monitoring, smart agriculture and smart ranch. They are capable of multi-gas real-time detection and provide reliable solutions for industrial and environmental applications.

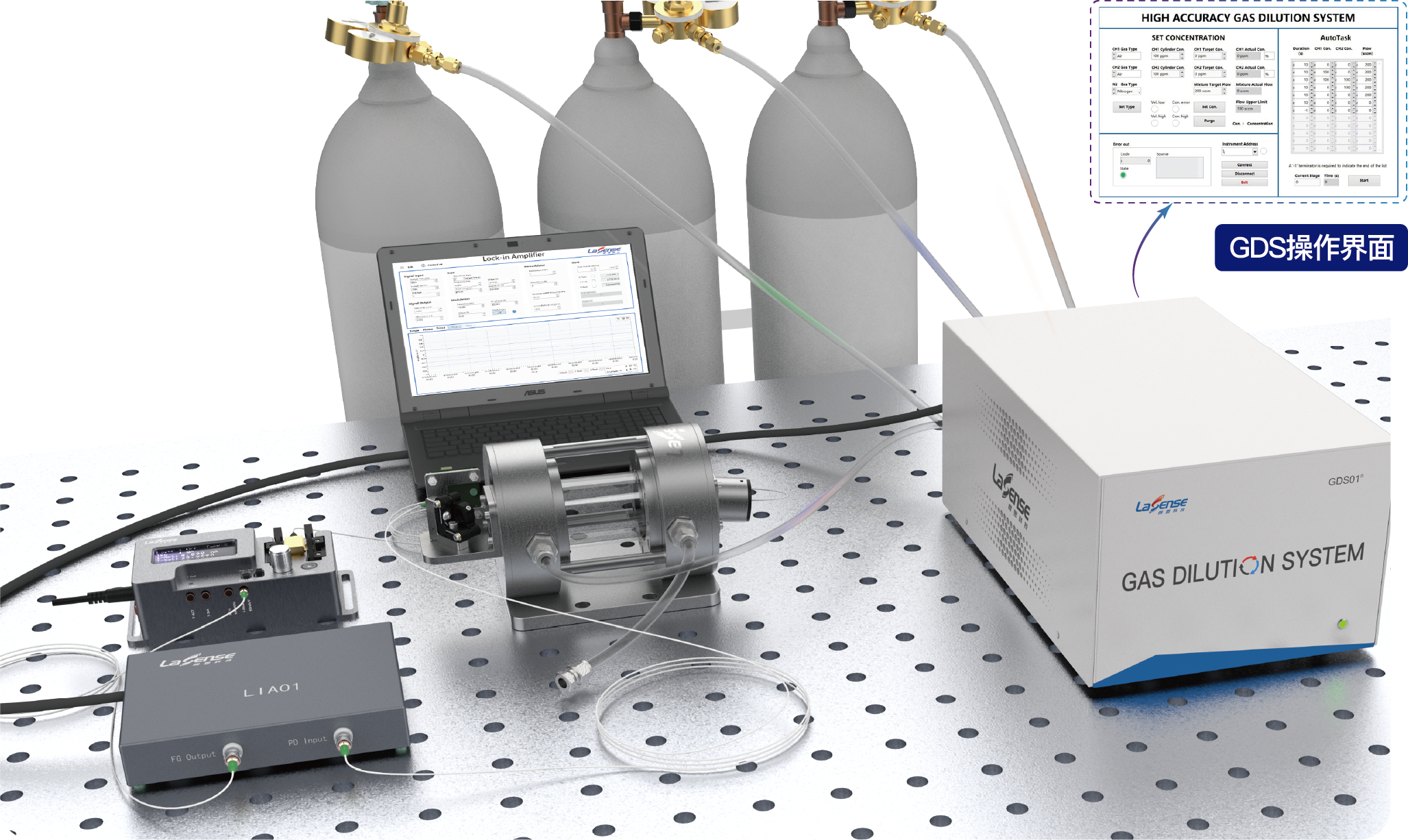

LaSense's research modular products (GDS01 High-Precision Automatic Gas Mixing System, M01 Ultra Low Noise Laser Driver, MPC-L Multi-Path Gas Cell, etc.) are specially designed for scientific research users, which help to quickly set up a high precision TDLAS system. These modular devices have excellent precision and stability, providing professional support for academic research, corporate R&D and cutting-edge exploration.

LaSense Technology offers customized products such as Dual-Comb Optical Frequency Comb System, Customized Optical Resonant Cavity, Photoacoustic Cavity, etc. to meet the unique needs of customers in complex gas monitoring and professional scientific research. These highly accurate and flexible solutions are suitable for a variety of application environments, such as gas analysis, basic science research and innovative experiments, helping customers break through technical limitations.

LaSense Technology is committed to promoting the application of laser spectroscopy technology in environmental monitoring and industrial inspection, providing high-precision gasanalyzers, sensors and customized products. Our products realize real-time, accurate and digitalmonitoring in many fields, provide reliable data support for energy safety, environmental protection management and scientificresearch experiments, and help the industry realize digital upgrading and technological innovation.